Business divisions

Load-bearing structures and sound insulation

The business division Support Structures and Noise Abatement offers complex solutions for examining and strengthening components and structures and assessing their structural stability and durability. Small and full-scale, mobile and non-destructive testing and measurement equipment for experimental verification of structural safety are available for this purpose.

Prof. Dr.-Ing.

Elke Reuschel

Head of division

T +49 (0)341 6582-143

F +49 (0)341 6582-181

Our working groups

In our 2,000 square metre testing laboratory, we carry out small to full-scale experiments on components and structures made of a wide range of materials and under all sorts of climatic conditions. In addition, our mobile testing and measurement equipment enables us to carry out load testing and vibration measurements directly on the structures. We also use monitoring systems to observe the structural safety of your structural installations. To allow for a comprehensive analysis of the performance of your materials and structures and to develop your products further, we will draw up an individual testing programme with you. We can also offer advice regarding CE labelling and approval issues.

- Testing technology – computer-aided, servo-hydraulic test cylinder installations, pulsators and testing machines for static and dynamic testing of test pieces up to 36 metres long and 9 metres wide using test loads of between 0.1 N and 14,000 kN

- Measurement technology – computer-aided measurement data collection with online presentation of force, elongation, extension, incline, crack opening, acceleration, vibration velocity, pressure, suction, temperature, humidity and amount of rain (short and long-term monitoring)

- Testing conditions – climatic chambers of various sizes with freely selectable temperatures between –40 and +80°C and up to 95% humidity

Dr.-Ing.

Immanuel Wojan

Head of working group

T +49 (0)341 6582-129

F +49 (0)341 6582-181

Load testing to determine load bearing reserves

(experimental assessment of structural safety)

It is a common problem that modification or refurbishment measures give rise to new loads (e.g. for repurposing) that are far greater than the original ones. As a result, the calculated stress may no longer be fully covered, or bending can become rather pronounced (fitness for use!). The structure’s bearing capacity can then no longer be determined through calculations. Components are either reinforced, disassembled or replaced. This approach is very time-consuming and expensive. Load testing may make such conversion measures unnecessary, if the structure’s bearing capacity is verified experimentally.

More information about load testin

Over the past few years, the MFPA Leipzig GmbH team has been able to gain plenty of experience with load testing. Our combination of theoretical knowledge and practical experience is virtually unparalleled in this field. Each experiment is a new challenge for our team, nevertheless.

The advantage of experiments compared to using a calculation model, is that there are no idealisations with regard to the structure and material. Another benefit of the material model is that spatial load transfer and the actual material strength are taken into account. Contributory floor constructions or a low tensile strength are also not considered in a calculation. In load testing they are revealed as load bearing reserves.

Time savings are the greatest advantage of load testing, apart from the cost factor. Following a certain preparation phase, the experiments are carried out in a timely manner. The result of load testing is available immediately after the experiments, and clients and planners will know for sure, whether the existing structure can handle future requirements.

Load testing is a non-destructive test procedure and is carried out in line with the guideline for load testing on concrete structures (“Belastungsversuche an Betonbauwerken”) issued by the reinforced concrete committee Deutscher Ausschuss für Stahlbeton (DAStb). The experimental target loads are determined by multiplying the load shares with the prescribed safety factors to verify the new specified loads. The load is applied in at least four steps. The reactions of the component are measured, presented and assessed online. The load deformation behaviour must comply with the specified deformation criteria of the DAStb guideline mentioned above. These criteria are designed to prevent damage to the test object and the intended use is ensured.

A load testing vehicle is used to test bridges with a span of up to 18 metres, producing experimental evidence of sufficient structural safety of previously damaged bridges, for example.

The online presentation of the load forces and the resulting deformation allows for statements regarding the bearing capacity of the tested component, immediately after the respective test load has been applied.

Prof. Dr.-Ing.

Elke Reuschel

Head of division

T +49 (0)341 6582-143

F +49 (0)341 6582-181

We will carry out standard-compliant measurements of airborne, footstep and structure-borne noise for you on different components and structures, both on site and on our test stations. We offer support and advice for developing new materials and designs, for example in the context of approval procedures.

Concerning your construction projects, we provide comprehensive acoustic guidance, we will prepare noise protection certificates, determine the cause of any noise protection deficits and we will also help you to create good acoustic conditions for your premises.

Our core activities also include the preparation of noise immission prognoses for commercial, traffic, sports and recreational noise and sound immission measurement.

- Recognised testing, monitoring and certification body in line with the State Building Regulations LBO and the EU Construction Products Regulation and recognised VMPA testing body for suitability testing of walls, doors, windows, ceilings, floor coverings and noise protection walls; preparation of General test certificate issued by the building authorities

- Accredited testing laboratory for measuring sound absorption in the reverberation space according to ISO 354 and sound measurement on noise protection walls according to the EN 1793 standard series, including on-site procedure and in line with the railway guideline

- Recognised VMPA noise protection testing body for acoustic measurements on construction sites

- Recognised measurement body for noise according to §29b of the German Emission Control Act BImSchG – valid across Germany

- Damage analyses and reports

Dipl.-Phys. Dietmar Sprinz

Head of working group

T +49 (0)341 6582-115

F +49 (0)341 6582-181

Just like other structural installations, buildings made of wood must comply with various requirements for users and with regard to building regulations. These include requirements concerning structural stability, traffic safety, fire protection, heat, noise and vibration protection, as well as protection against harmful impact of water, moisture, plant and animal pests and other chemical, physical or biological impact. The experience of MFPA Leipzig GmbH with wood as a construction material and with other renewable raw materials is pooled in the inter-disciplinary working group Timber Construction, in order to be able to develop technical solutions and reliable verification concepts. The group also offers consulting and advice services and coordinates the tasks of staff members from different business divisions and working groups.

The Timber Construction working group comprises wood experts from various disciplines represented at MFPA Leipzig GmbH, who are cooperating with our clients to draw up verifiably reliable solutions. We prepare reports and assessment documents to support you in obtaining usability and application certificates.

We would be happy to assist you with your timber construction project, too!

Dipl.-Ing. (FH) Volker Ahnert, M.Sc.

Head of working group

T +49 (0)341 6582-151

F +49 (0)341 6582-181

Our projects

The expertise and experience of our qualified team enables us to handle a wide range of complex tasks transparently, reliably, expediently and on time.

Dynamic bending test of a noise protection wall

In order to obtain an approval by the Federal Railway Authority, the business unit Supporting…

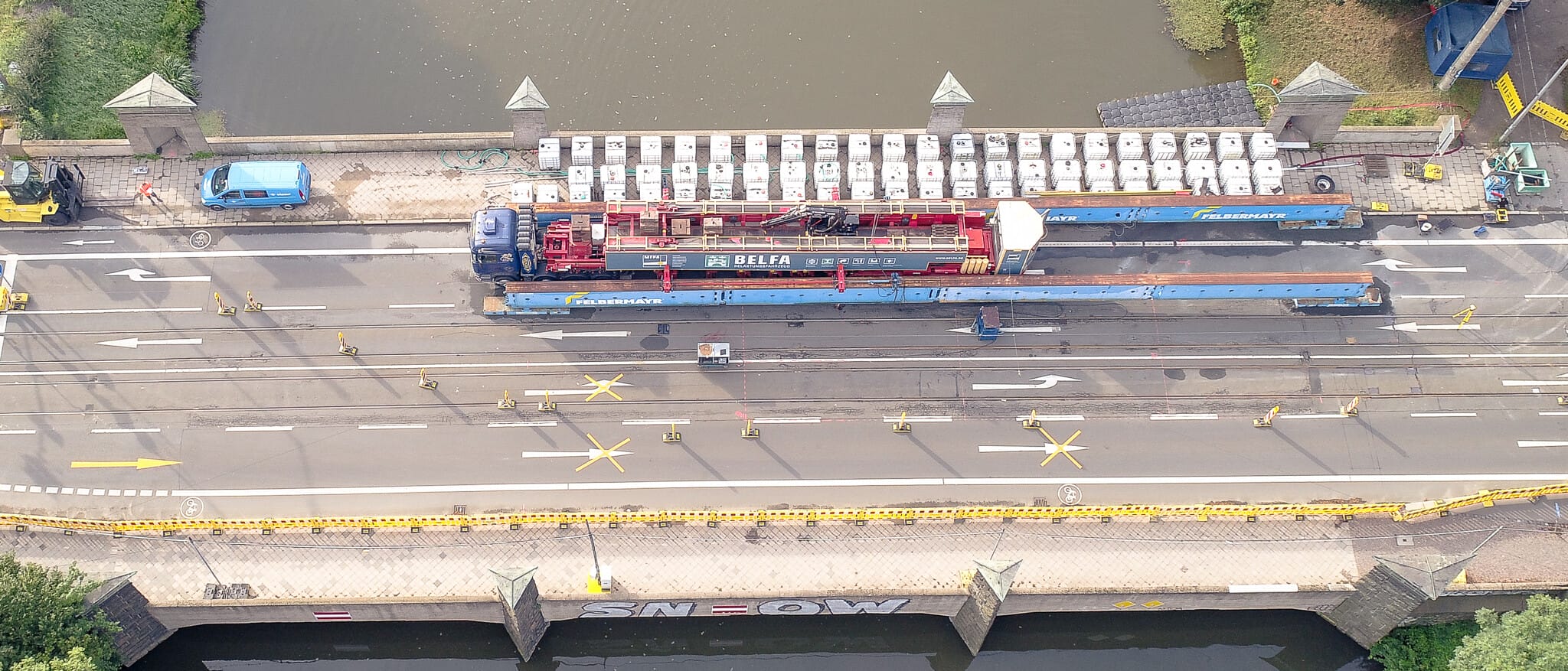

Load-bearing safety testing on bridge structures

In order to investigate the load-bearing capacity of the Leipzig Klinger Bridge in , a load test…

Pendulum impact test to verify impact resistance

To verify the impact resistance of the new glass facade of the Leipzig Gewandhaus, MFPA Leipzig…