Non-destructive, magnetic-inductive localisation of the reinforcement was carried out using a mobile Ferroscan P250/200 system by Hilti. There are generally two options for measurement data logging:

- Logging of a linear measurement. For this method, a measuring path on the surface of the component is followed using a scanner. The reinforcing steel that is aligned perpendicular to the direction of travel is identified and the concrete cover and longitude is recorded.

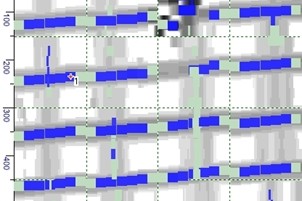

- Logging of a measuring surface. For this method, a measuring surface is scanned in perpendicular tracks. The measuring software uses the measurement data to calculate a graphic representation of the reinforcement in the concrete. Following the analysis, the concrete cover of the longitudinal and transverse reinforcement is identified.

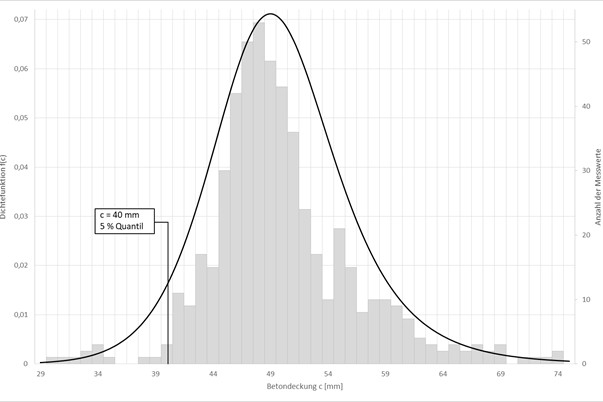

The size of the concrete cover and the rod intervals determine the quality of the measurement in particular. The recorded measurement data can be analysed according to the DBV information leaflet about concrete cover and reinforcement.

More projects

Assessment of mounting systems according to EAD 280016-00-0602

Characterization of the performance properties under ambient temperature and in case of fire

Pendulum impact test to verify impact resistance

To verify the impact resistance of the new glass facade of the Leipzig Gewandhaus, MFPA Leipzig…

Simulation of large-scale fires in road tunnels

Full-scale puddle fire test in the testing tunnel of MFPA Leipzig in order to validate existing CFD…