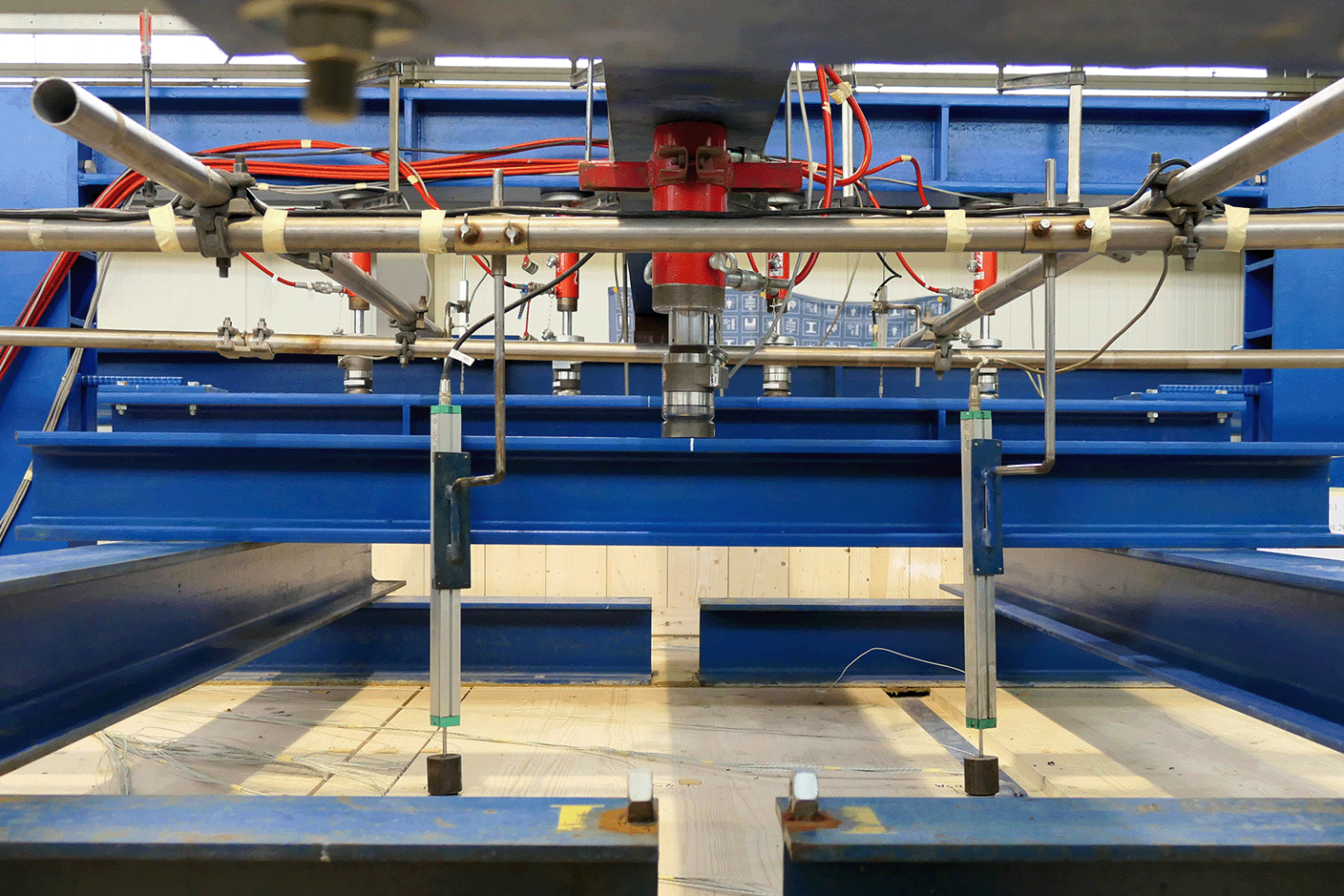

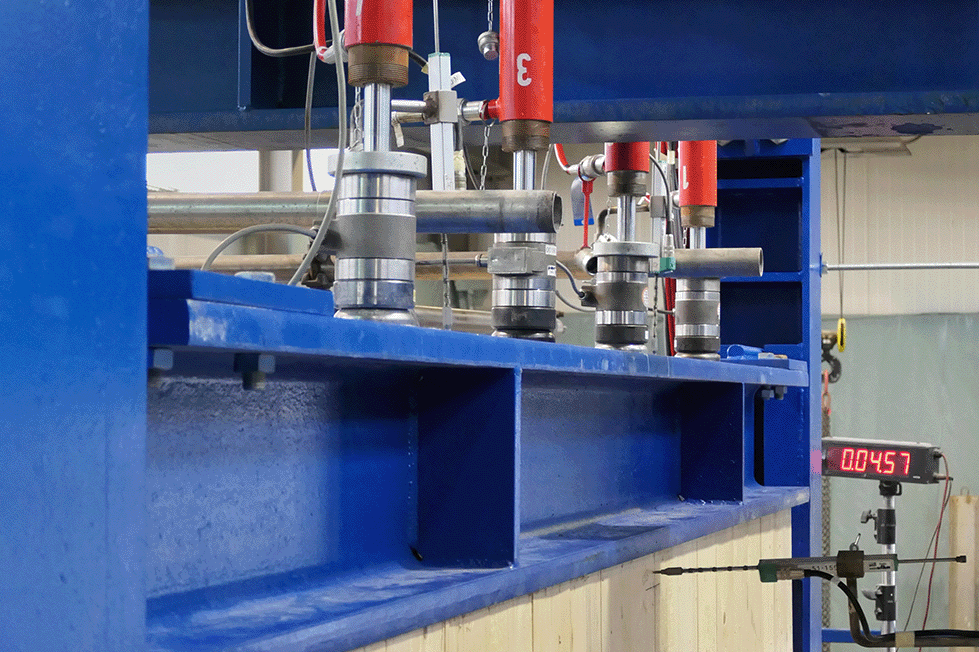

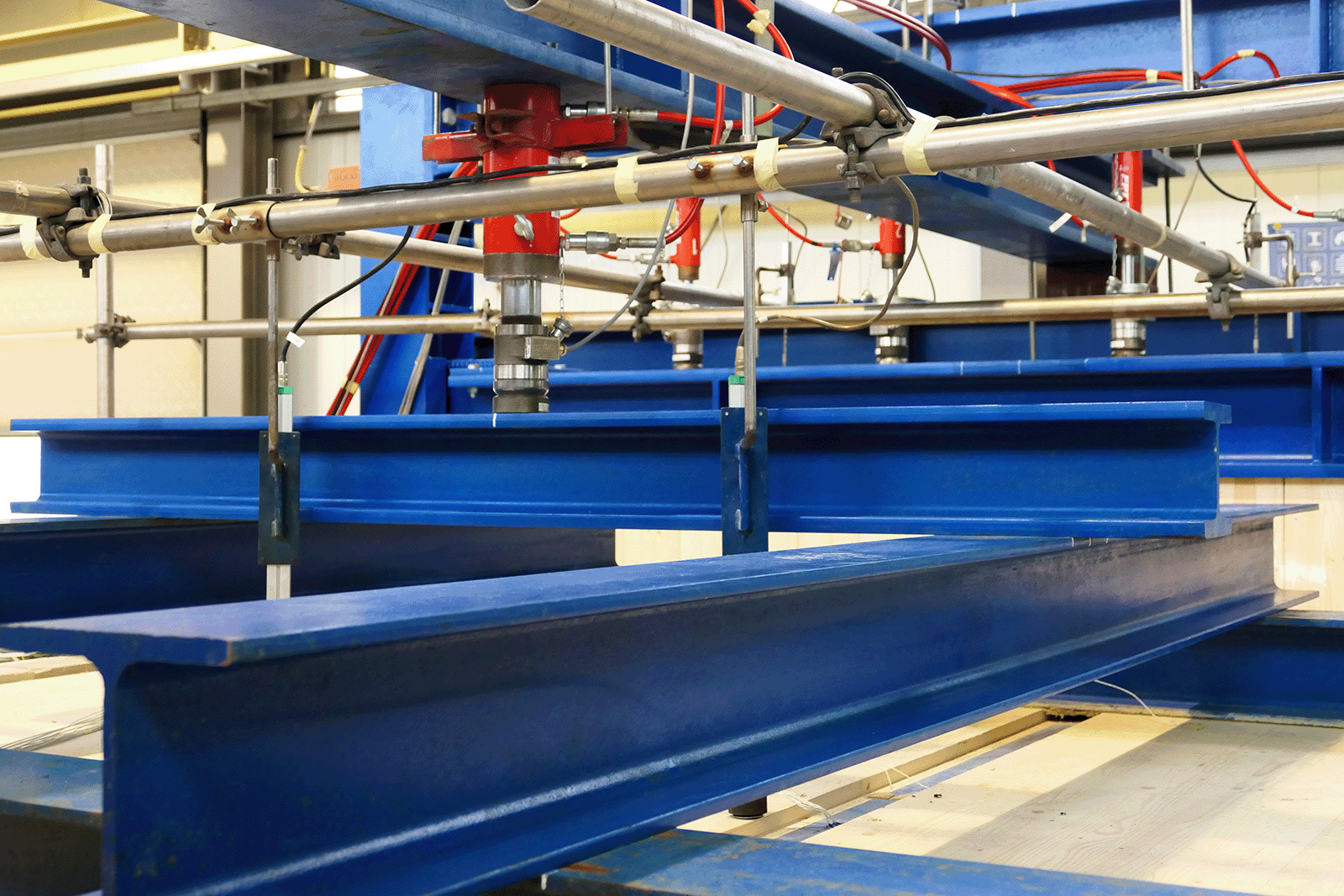

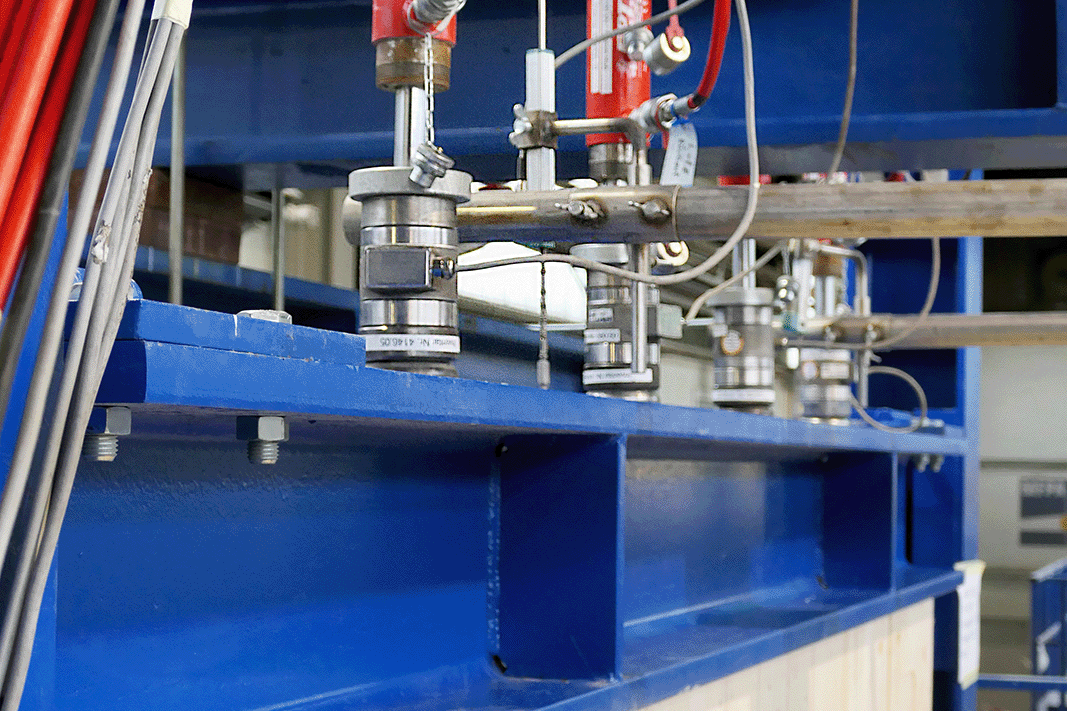

MFPA Leipzig GmbH developed a suitable test setup for verifying smoke tightness (with regard to § 14 of the model building code MBO), which is not possible using the fire resistance tests for wall and/or ceiling components provided for by the official standards. In addition to testing the ceiling and wall components, the goal was to also test the connection situation in a fire test under load.

In order to simulate a multi-storey design, realistic mechanical stress was applied to the wall and ceiling samples. It was thus verified that the requirements with regard to the bearing capacity, tightness of the room and the insulation criterion were complied with in a fully developed fire scenario according to the standards, not only on the individual ceiling and wall components but also with regard to the connection area.

The sample provided by Massiv-Holz-Mauer Entwicklungs GmbH consisted of a wall (nailed laminated timber construction) and a customary connection to a laminated timber ceiling (manufactured by Bestwood Schneider).

More projects

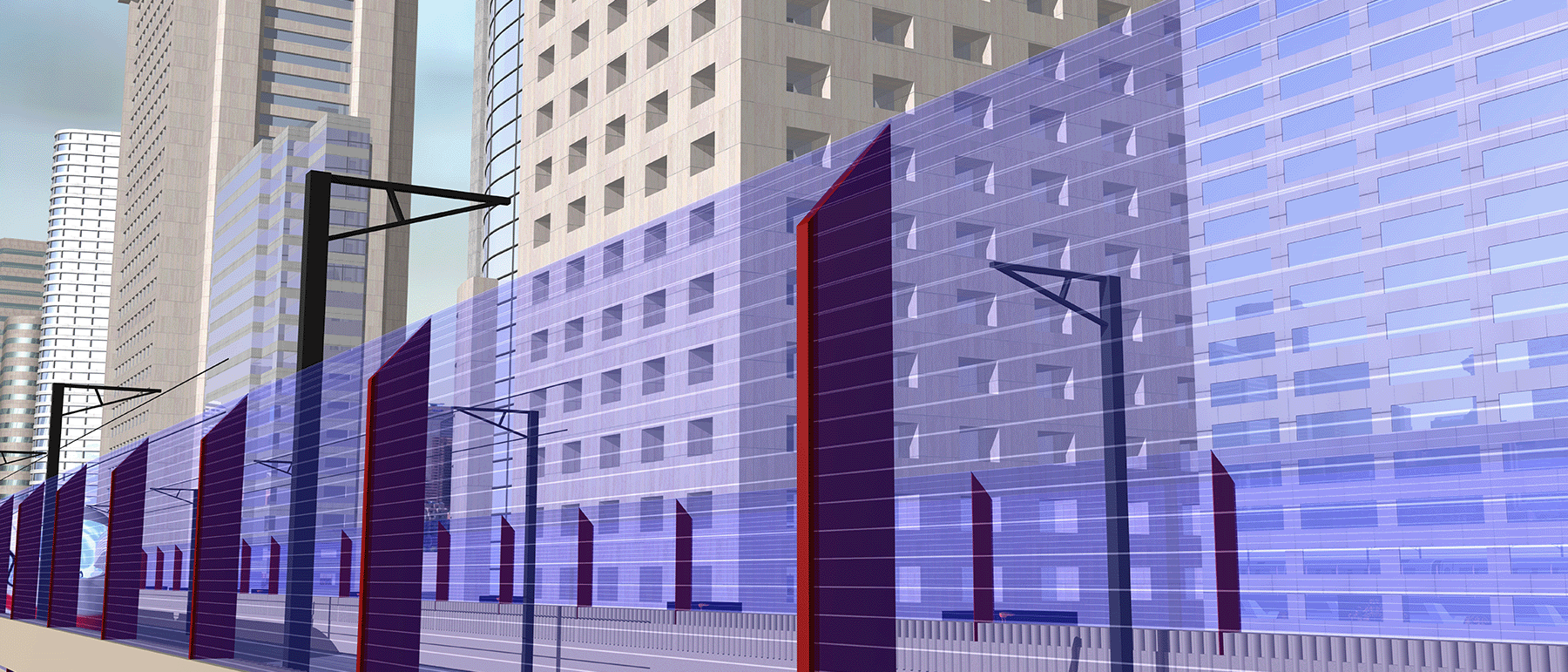

Laminated safety glass noise protection wall elements along railway tracks

The aim is to develop concrete proposals for providing proof of usability for the transparent…

Water-tightness testing on the tubing string

As part of the external monitoring service, MFPA Leipzig GmbH carries out recurring tests of…

Load testing in the context of converting the former Aktienspinnerei building in Chemnitz into the central library of the Chemnitz University of Technology

Experimental structural safety verification of historical cast iron columns in the old Chemnitz…