The application of innovative lightweight materials and concepts for rail vehicles was researched, developed and tested in experiments in cooperation with the Fraunhofer Institute for Machine Tools and Forming Technology (IWU), Voith Engineering Services GmbH, KUKA Systems GmbH and Lätzsch GmbH.

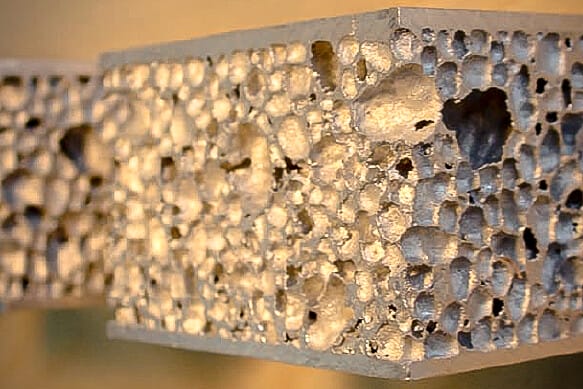

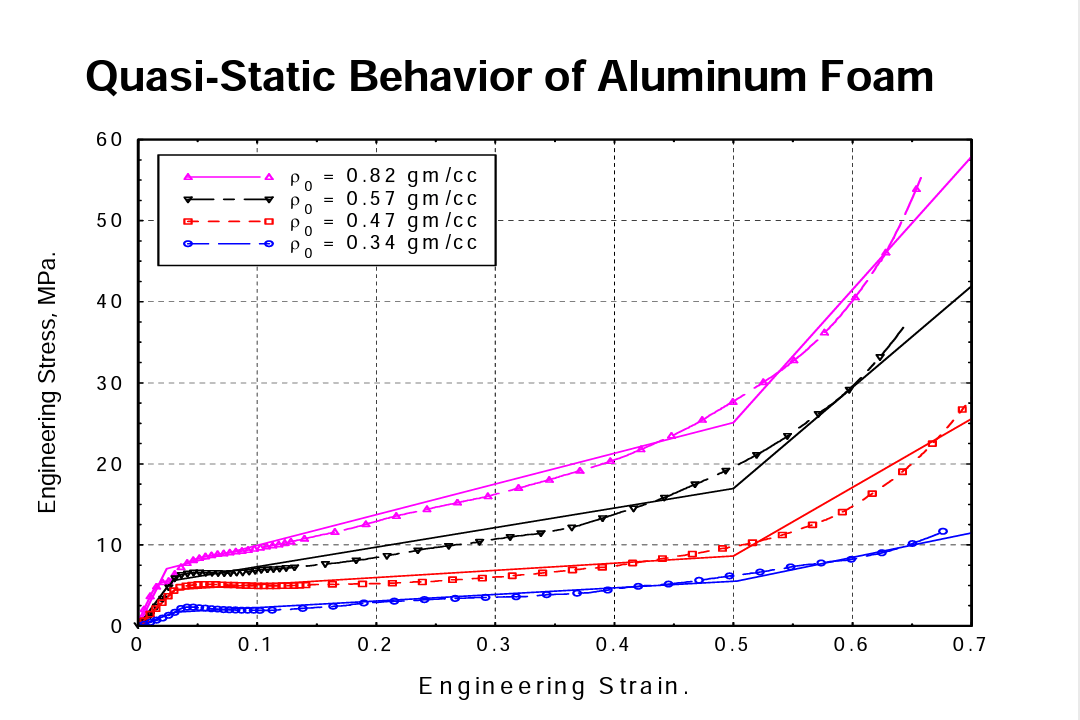

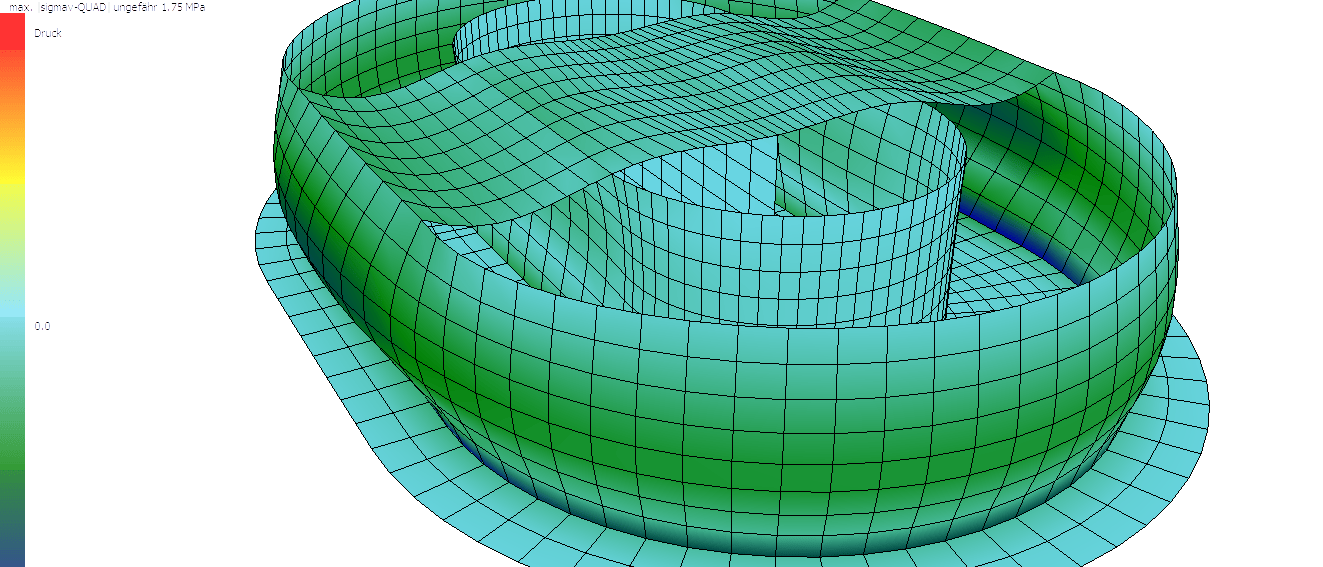

The key focus was a possible use of foamed aluminium sandwich elements that feature high weight-specific stiffness, great energy absorption capacity and good sound and vibration absorption properties, and can also be recycled relatively easily.

Our main task was to test the materials and composites under static load and impact stress, and to determine the natural frequency of the end car cabin that was built as part of the project.

Photos: Alulight international GmbH

More cooperation projects

Determination of the fire resistance of a loaded laminated beech veneer lumber column

To investigate the behavior of prefabricated prestressed concrete floors (prestressed concrete hollow core slabs) supported on DELTABEAM® composite steel girders, Peikko had an extensive fire test program carried out at MFPA Leipzig GmbH.

Simulation of large-scale fires in road tunnels

Full-scale puddle fire test in the testing tunnel of MFPA Leipzig in order to validate existing CFD models.

Project for optimising energetic biomass use

Monitoring of constructional parameters and optimisation of material properties when using steel fibre concrete in biogas technology.