Business divisions

Building materials and building physics

The core competences of the Materials and Construction Physics division are chemical, physical and mechanical-technological testing and examination of organic, non-organic and metal construction and other materials with regard to their performance parameters and durability properties, as well as the area of damage analysis.

Dipl.-Ing. Marko Orgass

Head of division

T +49 (0)341 6582-158

F +49 (0)341 6582-198

Our working groups

Our area of work covers sampling and non-destructive construction diagnostics of all types of buildings and structures, in particular masonry, concrete, reinforced concrete and prestressed concrete structures. Modern measurement, testing and analysis techniques, including non-destructive methods, are available in fully air-conditioned laboratories to enable us to test and examine a wide range of mechanical and physical influences on mineral-based materials, in particular on binder sets, concrete, all types of bricks, masonry and plastering mortars. A large number of different parameters is determined in the context of standardisation, initial, monitoring and approval inspections.

Our experienced staff members will help you answer any technical questions, as well as with production processes and product development.

- Recognised testing, monitoring and certification body for concrete and reinforced concrete as well as for building products for masonry construction in line with the State Building Regulations LBO and the EU Construction Products Regulation

- Damage analysis and reports – condition assessment, determination of the extent and cause of damage, analysis of transport and damaging mechanisms, conservation of evidence

- Accredited testing laboratory for mineral-based materials – production of mortars and concretes, testing of fresh mortar and fresh concrete, strength testing, testing of behaviour under climatic stress, determination of the deformation behaviour, light microscope examination

- Construction site examinations – structural investigation/condition review, conventional inspection of structures, non-destructive testing using various physical methods

- Research and development – production technology, mortar and concrete technology, repair systems, ageing processes of mineral-based materials, further development of safe and durable materials

Dipl.-Ing. Michael Becker

Head of working group

T +49 (0)341 6582-148

F +49 (0)341 6582-198

We will perform material and building diagnostic examinations of metal components and complete structures in structural, industrial and bridge construction for you, as well as of roof and façade designs, heating and sanitary installations, mechanical and plant engineering components, corrosion protection systems and coats. In addition to state-of-the-art testing technology in our laboratory, we can draw upon various non-destructive examination methods that are suitable for on-site use. We are happy to support manufacturers and processors in quality assurance. In addition, we are active worldwide in the field of monitoring and certification of metal building products and reinforcement technology.

- Recognised testing, monitoring and certification body in line with the State Building Regulations LBO and the EU Construction Products Regulation – e.g. for reinforcing steel/connections, metal building products, fibres for concrete, and design of steel and aluminium support structures

- Damage analysis – inspection and determination of the cause of building damage, expert reports for arbitration purposes, conservation of evidence, expert reports

- Accredited metal laboratory – mechanical-technological testing of reinforcing steel and reinforcing steel connections on existing steel support structures, non-destructive testing, microscopy, metallography on site and at the laboratory, emission spectrometry, corrosion testing, performance of acceptance tests, preparation of 3.1 reports

- Joining tests – verification of weldability

Dipl.-Ing. Manuel Neck

Head of working group

T +49 (0)341 6582-178

F +49 (0)341 6582-198

We have many years of experience in the area of chemical analysis investigation and in determining parameters of non-organic and organic materials. State-of-the-art measurement, testing and analysis techniques are available to carry out a wide range of examinations in our fully air-conditioned laboratories. The spectrum of available examinations ranges from non-organic binder sets, mineral-based and ceramic materials, through to waterproofing, coats, concrete additives and plastics. We perform construction chemistry and environmental chemistry analyses for you in the context of building diagnoses, condition assessments and compatibility determination of construction materials.

- Accredited laboratory for wet-chemical and instrumental analyses and verification, durability and ageing experiments

- Recognised testing, monitoring and certification body in line with the State Building Regulations LBO for glued on concrete reinforcements, segment construction

- Wide range of examinations – quality and quantity-based determination of organic and non-organic material content, damaging salts, waterproofing, coats and corrosion protection, concrete additives, water

- Construction chemistry tests – age-dependent parameters of textile fabrics and plastics, weathering, chemical resistance, temperature and environmental impact, diffusion processes, material corrosion, penetration behaviour of water-polluting substances, acid-resistance of concrete

- Inspection and assessment – paint and coating damage, corrosion and expansion effects in concrete, mutual compatibility of construction materials

Dr. rer. nat. Jana Schneider

Head of working group

T +49 (0)341 6582-145

F +49 (0)341 6582-198

Our competent and dedicated engineers provide complex solutions for examining, assessing and strengthening components and structures. Damage is identified and its causes are determined to assess the structural stability and durability of your structures. Based on this we will then draw up concepts for strengthening and repairing or renovating the structure, and will monitor their implementation on your behalf.

- Recognised testing, monitoring and certification body in line with the State Building Regulations LBO and the EU Construction Products Regulation – monitoring body for class 2 and 3 concrete, crack filling materials, reinforcing elements for shear reinforcement in the support area and for composite girders

- Inspection of engineering structures pursuant to DIN 1076 – all types of bridge structures, as well as tunnels, support walls and passages, documentation in line with the inspection guideline RI-EBW-PRÜF or based on the client’s specifications, property-specific damage analyses (OSA)

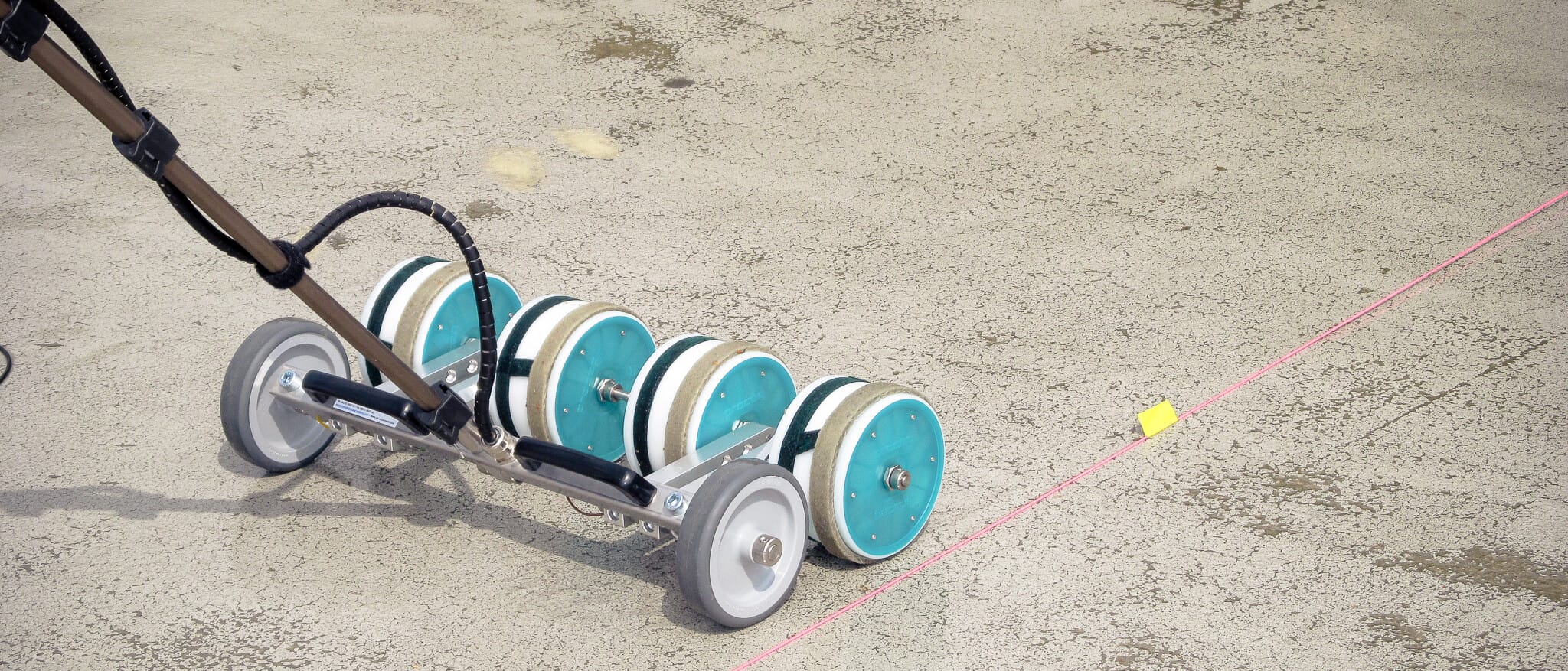

- Inspections, building diagnoses, conservation of evidence – determination of the condition of a structure, inspection and determination of the cause of building damage, evidence conservation reports, non-destructive and minor-destructive testing (e.g. measuring concrete cover, determination of compressive strength and tear strength of concrete), measurements to identify active corrosion and assess the risk of corrosion (potential field measurement and measurement of the specific electrical resistance of concrete)

- Construction monitoring – repairing concrete structures according to the ZTV-ING guidelines, damage-specific solutions, in-process monitoring of new construction and repair measures

Dipl.-Ing.

Matthias Rudolph

Head of working group

T +49 (0)341 6582-152

F +49 (0)341 6582-198

Forms for concrete construction sites

Reporting of class 2/3 concrete work monitoring

Concrete casting notification

Results reporting

Application for determination of concrete compressive strength at a concrete age other than 28 days

We are your partner for all testing and monitoring tasks for thermal and impact sound insulation materials and are happy to provide you with competent support for certifications and approvals. In addition, we offer you the measurement of thermal, hygric and mechanical material parameters in our laboratory.

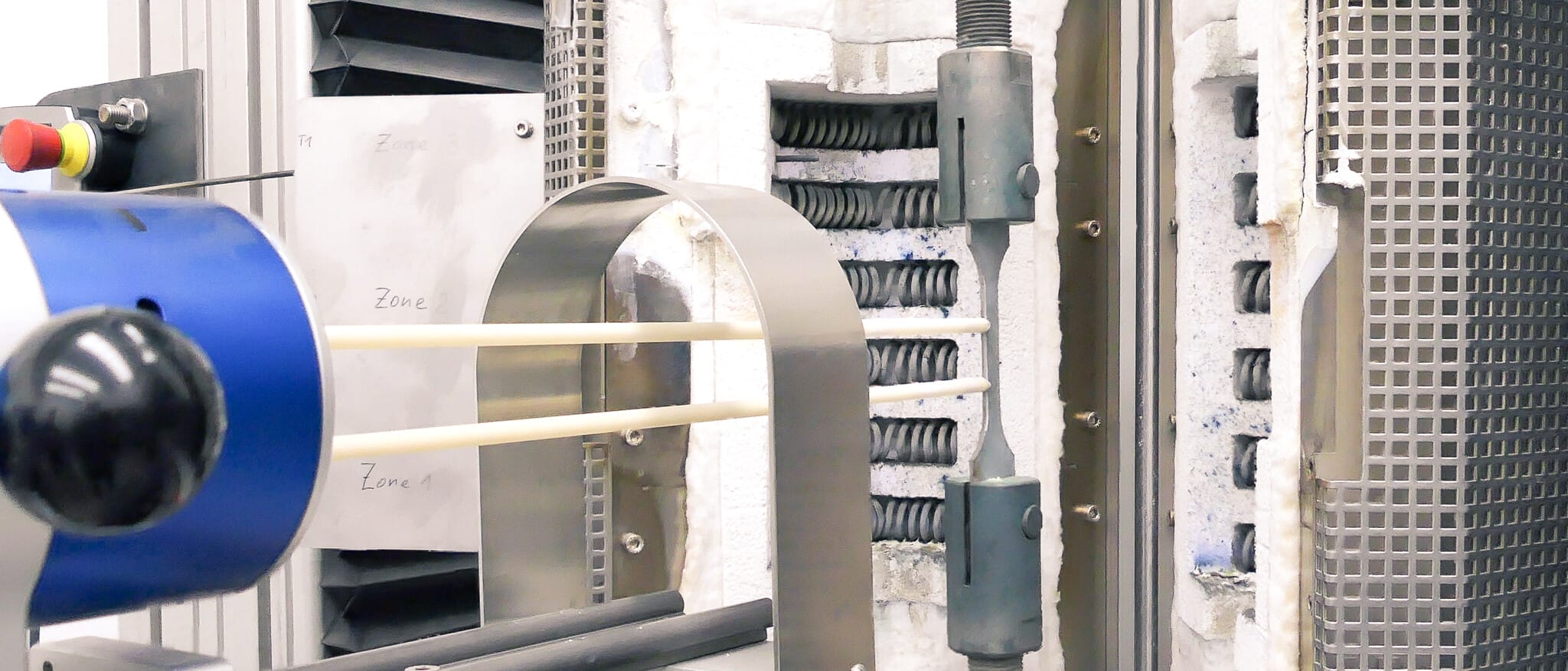

We also have great experience in measuring the water vapor diffusion resistance on insulation materials and foils. In our EOTA double wall test rig, we examine ETICS and VHF systems according to various ETAGs. Hygrothermal simulations, thermal bridge calculations and expert opinions on all thermal and moisture protection issues complete our profile.

- Recognized PÜZ body according to LBO and EU-BauPVO for insulation materials for thermal and sound insulation

- Determination of thermal, hygric and mechanical properties of insulation and building materials

- Water vapor permeability test – sd-value, µ-value

- Testing of thermal conductivity in the temperature range from -15 °C to +60 °C

- Numerical simulation – modeling of heat transfer processes, thermal bridge calculation

- On-site investigations – sampling, long-term climate monitoring

- Approval tests for facade systems in the hygrothermal wall test rig

Dr.-Ing. Stephan Reichel

Head of working group

T +49 (0)341 6582-190

F +49 (0)341 6582-198

Our projects

The expertise and experience of our qualified team enables us to handle a wide range of complex tasks transparently, reliably, expediently and on time.

Stress corrosion examination on bridge structures

In order to assess the current condition of the structure, prestressing steel, grout and parts of…

Measuring the temperature and hydration heat development of concrete

Web-based long-term measurement (monitoring) of the temperature or hydration heat development of…

Non-destructive measurement of permeability of concrete

Non-destructive measurement of permeability for the evaluation of concrete properties with respect…

Potential field measurement for assessing corrosion processes

Non-destructive potential measurement is used to assess corrosion processes on the reinforcement of…

High temperature tensile tests at up to 1,350°C

Investigation of the temperature-dependent mechanical properties of steel materials

Concrete-technology support for PP fibre concrete tunnel construction projects

Concrete technology support for tunnel construction projects using PP fiber-reinforced concrete,…

Analysis of concrete cover, reinforcement layer and diameter

Non-destructive determination of the position and cover of reinforcing bars in concrete. The…