Load testing can be used to reliably determine the bearing capacity of bridges, usually identifying significant reserves compared to calculations. Decisions for or against demolition/replacement or repair/reinforcement can be made quickly and objectively, based on verifiable criteria.

The BELFA load testing vehicle was developed to perform on-site load tests more quickly and cost-efficiently. Using the load testing vehicle helps to reduce blocking times that are undesirable for economic reasons, and a perforation of the sealing layer can usually be avoided, too.

Contact person

Prof. Dr.-Ing.

Elke Reuschel

T +49 (0)341 6582-143

F +49 (0)341 6582-181

Further information

Longer operating life

Higher load capacity

Objective and risk-free testing

Short blocking periods

Quick result

| Driving status | l = 22,5 m |

|---|---|

| Testing status | l = 22,5 bis l = 35,8 m |

| Support (brackets) | a = 6,0 to a = 18,00 m |

| Vehicle mass (without ballast) | G = 73 t |

| Steel ballast | P = 7,8 t |

| Water ballast | P = 20 t |

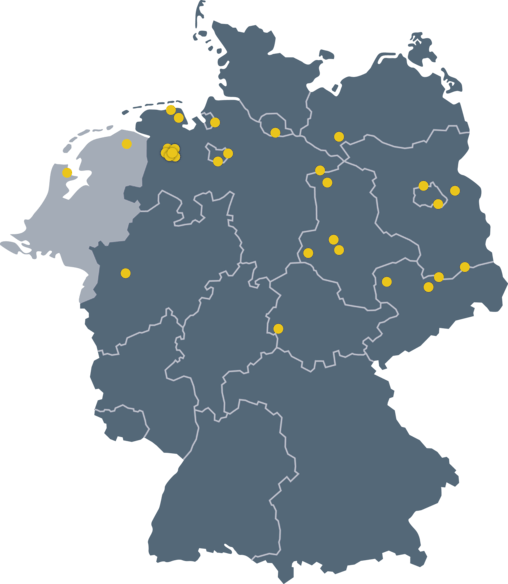

Since its first use in 2001, about 60 bridges made of reinforced concrete, prestressed concrete, compressed concrete and masonry have been examined using the BELFA. Project partners from the Bremen City University of Applied Sciences, TU Dresden, Bauhaus University Weimar and HTWK Leipzig/MFPA Leipzig were involved in these tests.

Compared to pre-calculations, the load capacity verified was 30 to 50% higher, and in individual cases up to 150% higher, without reducing the level of safety.

The BELFA was comprehensively modernised and converted in 2015, and has since been operated by MFPA Leipzig GmbH. It was first used on the Gustav Esche Bridge in Leipzig in August 2015.

FAQ

Structures are usually calculated statically. However, calculation models for structures rely on simplifications regarding the geometry, construction material behaviour, load transfer, and so on. This is justified, as a useful life of around 100 years is assumed when planning new structures, and the model assumptions also provide for higher loads and busier traffic in the future, as well as taking ageing effects of materials into account.

The goal of load testing on existing structures with a past usage history, is to make statements about their current load-bearing capacity with a perspective for continued use for up to 20 years.

Load testing on a newly built structure made of new construction materials or of innovative design allows for the model assumptions made to be verified or improved

Load testing is therefore not an alternative to statical calculations, but a useful supplement if model assumptions are unclear or if the following conditions apply:

- Poor structural condition and weakened bearing cross-sections due to corrosion, crack formation, concrete spallation, moisture penetration, etc.

- Damage to the structure following unusual events (fire, explosion, flooding, impact, changes to the subsoil)

- Incomplete or missing planning documentation that cannot be fully restored (reinforcement structure, prestress, special components)

- Innovative construction materials, composite material solutions, lack of experience with particular designs

- Admissible traffic load or load capacity

- Possibly necessary traffic restrictions or refurbishment measures

- Confirmation of successful refurbishment measures (e.g. for unclear compound structures)

- System identification

- Remaining useful life if combined with monitoring

This means that load testing provides for an objective, verifiable basis for decision-making for public authorities at short notice, concerning demolition/refurbishment/continued use for a limited or unlimited time. Decisions regarding the efficient use of existing resources can be made at a high level of planning security. If needed, building monitoring can take place after load testing, to observe the progress of any damage or overloading by vehicles (possibly in cooperation with the police).

- Support spans of the bridge spans up to 18 m (for larger support spans special solutions for load investigations can be individually configured – please inquire!)

- Verification of bridge classes 12 to 60 according to DIN 1072 (recalculation guideline) or load models according to Eurocode or DIN technical report (maximum load in one lane up to 1500 kN, secondary lane and remaining areas via stepwise ballasting)

- Bridge width up to 8 m (for larger widths special solutions possible – please inquire!)

- Access route for semitrailer and BELFA with sufficient load-bearing capacity.

- Approval of the vehicle according to StVZO in all federal states until 2027 is available

This means that in addition to bridges and culverts, other engineering structures or sewers, piles and other foundations, roof structures, ceilings in industrial construction, hydraulic structures, etc. can also be subjected to test loads.

- Self-securing loading technology with state-of-the-art control, combined with measuring technology and experienced staff damage caused by load testing can be ruled out

- Very short blocking times

- No need to penetrate the bridge’s sealing layer for verification up to bridge class 30

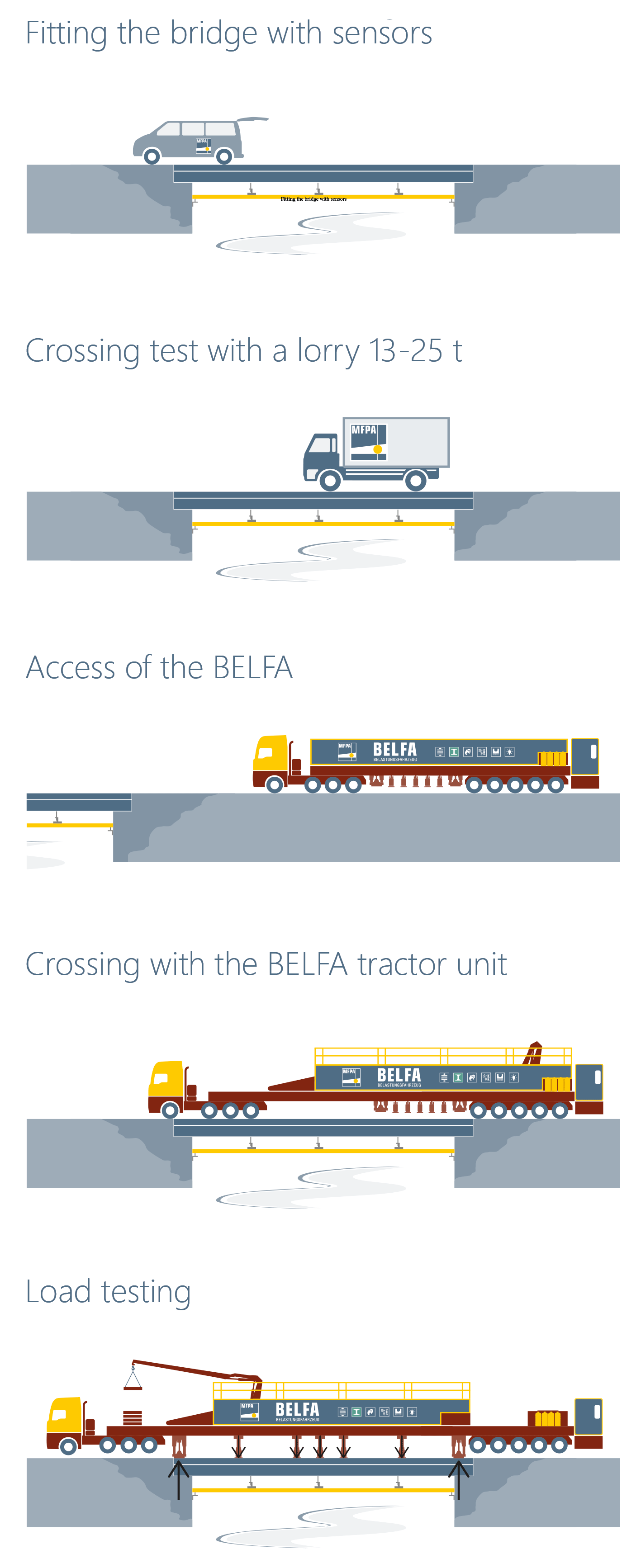

- Site visit

- Review of existing documentation

- Structure diagnosis to verify the information from the documents

- Drawing up an initial calculation model – determination of the required load positions and of weaknesses for measurement monitoring during testing, test design

- Coordination of testing targets and test design with the authority/structure planner/testing engineer

- Application for blocking periods and the travel routes of the BELFA

- Setting up the measuring technology and measurements with normal traffic and with a vehicle with defined axle loads (own lorry)

- Access of the BELFA and measured crossing of the bridge in question with the tractor unit with load removed as far as possible

- Setting up the entire vehicle on the 4 props off the object that is to be examined or over the supports/thrust blocks as a counterweight to the 5 hydraulic test axles (self-securing load principle)

- Performance of load testing based on the guideline for load testing on concrete structures by the reinforced concrete committee, comparison/ changes to the calculation model if necessary

- Return of the BELFA, handing over advance information about the result

- Preparation of the test report/expert opinion and hand-over consulting

- Traffic blockage on the bridge: about 1-2 days in total on one lane, about 10 hours of full blockage (possibly at night/at the weekend), depending on the task at hand

- Traffic blockage below the bridge: installation of measuring technology, by arrangement depending on the task

BELFA: added test load + vehicle-specific parameters

Structure: depending on requirements:

- Bending

- Crack formation and crack displacement

- Joint movement

- Elongation/compression

- Inclination changes

- Support movement

- Support forces

- Acoustic emission

- plus vibration velocity and acceleration in the case of dynamic excitation

- Load testing has been done in construction for more than 100 years.

- It was first regulated for reinforced concrete construction in DIN 1045 (1925).

- Load testing was no longer specified in the new version of DIN 1045 (1972), and it was effectively not practised in the FRG.

- Load testing in the GDR was legally regulated in the technical standard TGL 334077/04 (1985) “Verification of load-bearing capacity and usability based on experimental testing” and practised widely.

- The scientific foundations for load testing with modern load production and measuring technology in structural engineering and bridge constructions were established in the research projects EXTRA I and II. The approach is governed by the guideline for load testing on concrete structures issued by the reinforced concrete committee “Deutscher Ausschuss für Stahlbeton” (2000).

- Structure design aided by testing is provided for by EC 2, section 2.5 (2013).

- Load testing for existing road bridges is approved in the guideline for recalculation of existing road bridges (“Nachrechnungsrichtlinie”, 2011), approval from the highest road construction authority must be sought.

- Load testing must not cause any damage that may have an impact on future use.

- Load testing should be carried out in combination with construction diagnostics to detect any pre-existing damage.

- The load technology used should be self-securing and allow for precise adjustments.

- Load testing should currently be limited to components showing signs of prospective failure. Research is currently being carried out for use on components without indication (shear and compound failure). Areas at risk of brittle fracture must be equipped with measuring instruments.

- Temperature-dependent contributory effects of coats and trims must be taken into account when evaluating the tests.

- Load testing should be carried out by experienced experts only.

- 5 new controller circuits for hydraulic cylinders with a sampling rate of 8 kHz

- Digital position sensors with a resolution of 0.0005 mm

- Each hydraulic cylinder can be operated individually with regard to track and force control

- Modern computer with new operating software

- Special permission for all federal states until 2027 in line with §70 of the German traffic regulation StVZO

- Minor modifications of vehicle control and safety technology

- Each structure and each assignment is unique. This is why we do not have any fixed prices.

- Testing costs roughly as much as a passenger car.

- We are happy to advice you and draw up a quote.

- Please send us designs, photos and documents about your structure and information about the reason why you are considering load testing.