Below you will find an overview and detailed information about the different types of façade fire tests offered by the Constructional Fire Protection division of MFPA Leipzig GmbH. We can perform façade fire tests based on different standards and specifications. The results are summarised in a detailed test report.

Overview of facade fire tests

Facade fire test according to DIN 4102-20

This type of façade fire test is a test procedure for assessing the fire performance of exterior wall cladding. It is suitable for assessing the level of resistance of the lintel or the fire protection measures in the lintel area, and is used as verification for the material class “hardly inflammable”.

Based on a model, the strain on the façade is tested that is caused by flames flickering out through a wall opening. The goal is to determine how the exterior wall cladding contributes to fire spreading on the façade.

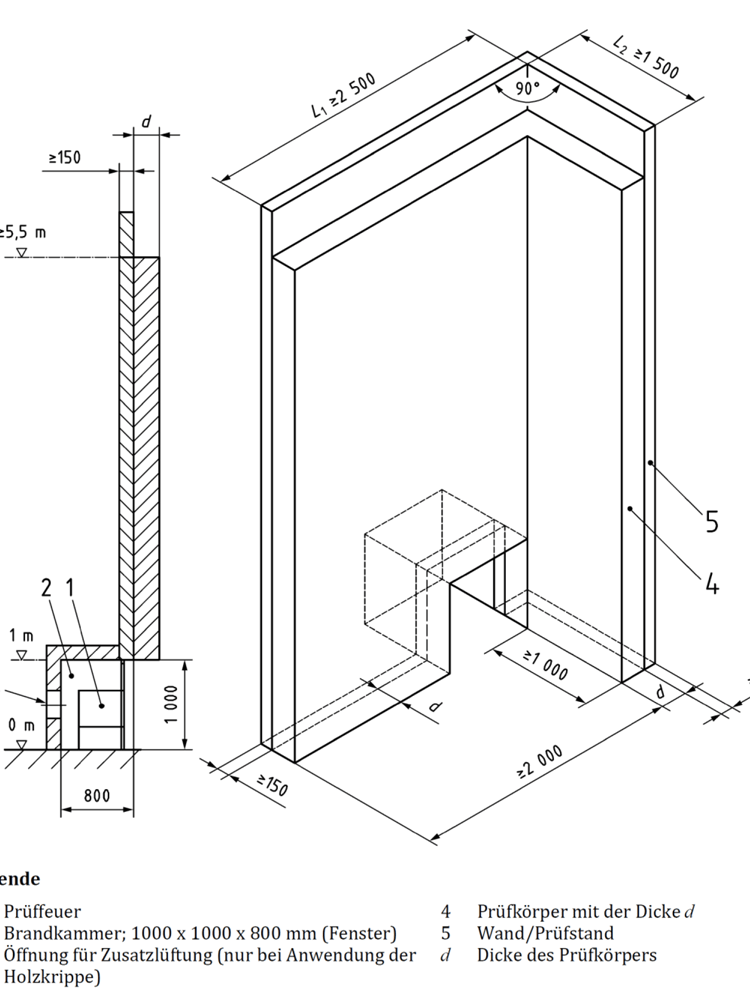

An interior corner of the building is recreated for this purpose. The opening that is referred to as a fire chamber is positioned directly in the corner. A gas burner (340 kW) is placed inside the fire chamber. Spreading of the fire is recorded through measurements and visually during the test. The results are summarised in a test report.

In approval procedures, the test results can be used alongside other fire testing results to form the basis for assessing exterior wall cladding as hardly inflammable.

Depending on the testing process and possible variations of the structure that is to be assessed, a single test may suffice.

The testing duration is 20 minutes, during which the test piece is exposed to direct flames. The testing period is followed by an observation period of at least 40 minutes and up to 15 hours.

The gas burner with a heat release rate of 340 kW (formerly a 30 kg wooden crib) is positioned in a fire chamber on the floor of the testing station. The flames emerge from the opening that is a metre high and wide onto the lintel, affecting the area of the exterior wall cladding above it.

The test piece is designed as an inside corner. The visible surface of the longer side is at least 2.0 m wide and the visible width of the shorter test piece side must be at least 1.0 m. The test piece is at least 5.5 m tall. There are no restrictions regarding its thickness, which depends on the exterior wall cladding that is to be examined.

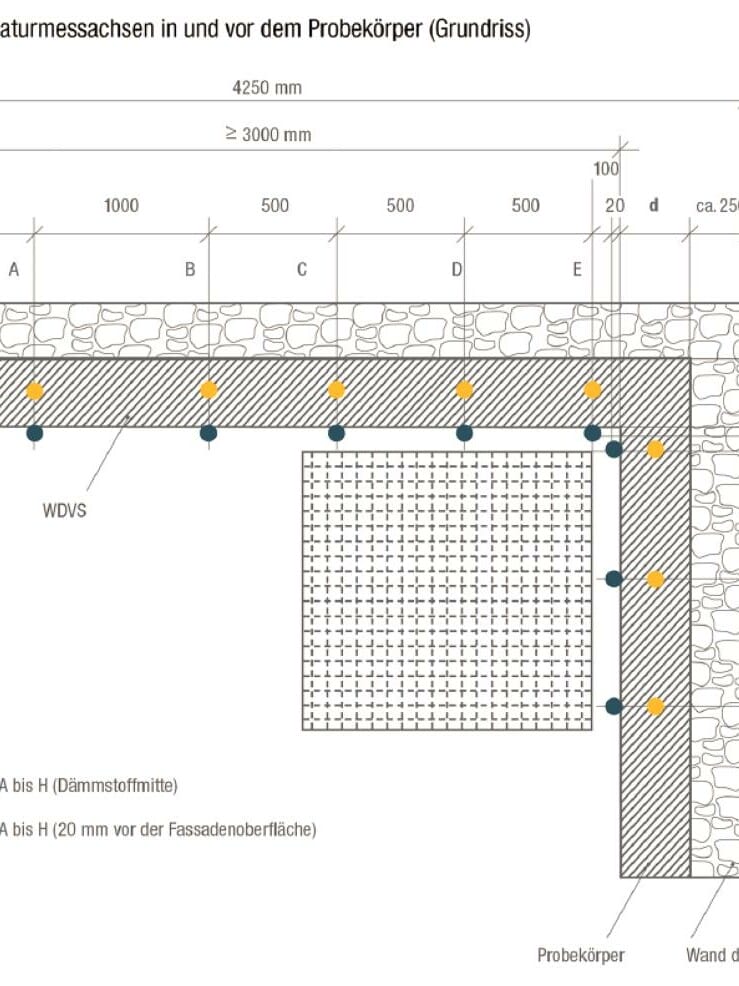

The results of the test are presented in a comprehensive test report. The test report includes a detailed description of the test set-up, the temperatures on and inside the façade, observations of the spread of the flames or burning droplets, and the damage pattern after the end of the test. In addition, each test is documented in the form of continuous video recording.

The results of this test can be used supplementary to the assessment of the construction materials used and the exterior wall cladding system according to DIN 4102-1 or DIN EN 13501-1 to form the basis for assessing the fire performance of exterior wall cladding systems, including structural fire protection measures such as fire barriers.

The types of exterior wall cladding tested include thermal insulation systems and mounted, ventilated façades in particular. However, tests have also been done on photovoltaic systems, advertising elements, films, shading elements and construction types such as double-shell masonry and formwork blocks.

Facade fire test according to EDIN 4102-24 or MVV-TB, attachment 6

This type of façade fire test is a test procedure for assessing the fire performance of exterior wall cladding in the event of exposure to fire in the immediate vicinity of the base of the façade (fire outside the building). The test is designed in particular to assess the resistance of the base or the fire protection measures taken in the area of the base, but the test is also used as verification for the material class “hardly inflammable”.

The strain on the façade from flames caused by garbage containers positioned directly in front of the façade is tested at the original scale. The goal is to determine how the exterior wall cladding contributes to fire spreading on the façade.

An interior corner of the building is recreated for this purpose. The burning wooden crib (200 kg) in front of it is used to simulate a fire. Spreading of the fire is recorded through measurements and visually during the test. The results are summarised in a detailed test report.

In approval procedures, the test results can be used alongside other fire testing results to form the basis for assessing exterior wall cladding as hardly inflammable.

Depending on the testing process and possible variations of the structure that is to be assessed, a single test may suffice.

The testing duration is at least 25 minutes, during which the test piece is exposed to direct flames from a wooden crib. The testing period is followed by an observation period, which ends no sooner than 60 minutes after the start of the test.

The 200 kg wooden crib is positioned on the floor in the inside corner of the test station. The flames affect the part of the exterior wall cladding above.

The test piece is designed as an inside corner. The long side is at least 4.0 m long, the shorter side is at least 2.0 m wide. The sample test piece is at least 9.8 m tall. There are no restrictions regarding its thickness, which depends on the exterior wall cladding that is to be examined.

The results of the test are presented in a comprehensive test report. The test report includes a detailed description of the test set-up, the temperatures on and inside the façade, observations of the spread of the flames or burning droplets, and the damage pattern after the end of the test. In addition, each test is documented in the form of continuous video recording.

A certificate of “Sockelbrand” testing has been required for the approval procedure for EPS-based thermal insulation systems since 2016, if a

deviation from the standard fire protection measures is desired. This means that this type of test must be carried out if, for example, a different type or number of fire blocks or an innovative EPS insulating material is to be approved for use.

The standard fire protection measures are outlined in the report about the structural design of measures for improving the fire performance of thermal insulation systems with EPS insulating materials that are classified as hardly inflammable issued by DIBt on 27 May 2015 (“WDVS mit EPS-Dämmstoff. Konstruktive Ausbildung von Maßnahmen zur Verbesserung des Brandverhaltens von als „schwerentflammbar“ einzustufenden Wärmedämmverbundsystemen mit EPS-Dämmstoff”).

The “Sockelbrand” testing process is currently provided for by the draft version of the technical building regulations (“Technische Baubestimmungen”, MVV TB – A.2.2.1.5) and is to be translated into an official standard (draft title: DIN 4102-24). The process is currently used for national approval of EPS-based thermal insulation systems only.

Facade test according to BS 8414-1

This type of facade fire test is a test procedure for assessing the fire performance of exterior wall cladding on masonry.

A fully formed room fire whose flames are affecting the façade through a window opening is simulated for this purpose. The goal of the procedure is to determine the contribution of the exterior wall cladding to the spread of fire on the façade as well as the risk of it burning through.

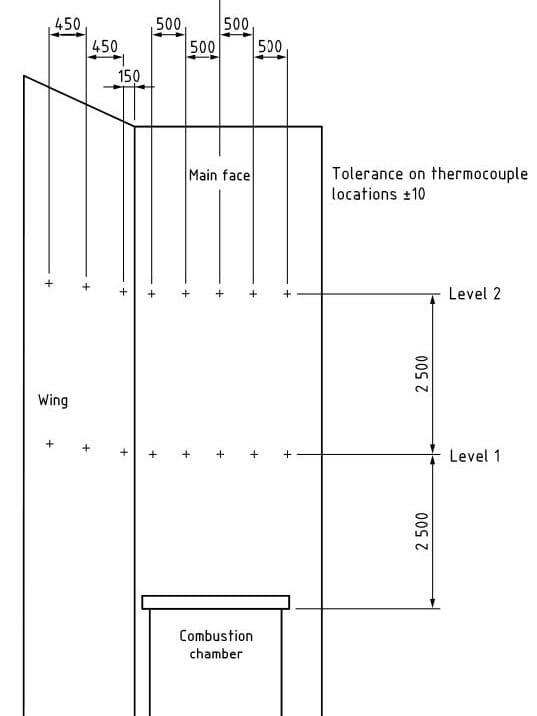

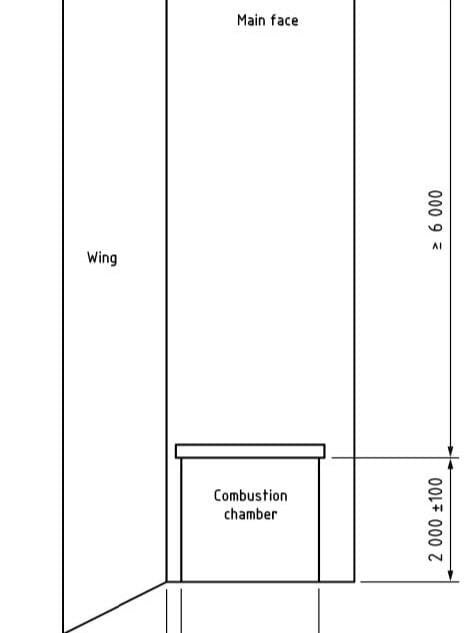

An interior corner is recreated for this purpose. The opening that is referred to as a fire chamber is positioned in the corner. A wooden crib (400 kg) is placed inside the fire chamber. Spreading of the fire is recorded through measurements and visually during the test. The results are summarised in a detailed test report.

Depending on the testing process and possible variations of the structure that is to be assessed, a single test may suffice.

The testing duration is 30 minutes, during which the test piece is exposed to direct flames. The testing period is followed by an observation period of up to another 30 minutes.

The 400 kg wooden crib is positioned in a fire chamber on the floor of the testing station. The flames emerge from the opening that is a metre high and wide onto the lintel, affecting the area of the exterior wall cladding above it.

The test piece is designed as an inside corner. The visible surface of the longer side is at least 2.4 m wide and the visible width of the shorter test piece side must be at least 1.2 m. The test piece is at least 8.0 m tall. There are no restrictions regarding its thickness, which depends on the exterior wall cladding used.

The results of the test are presented in a comprehensive test report. The test report includes a detailed description of the test set-up, the temperatures on and inside the façade, observations of the spread of the flames or burning droplets, and the damage pattern after the end of the test. In addition, each test is documented in the form of continuous video recording.

Classification takes place according to BRE 135. The purpose of the results of testing pursuant to BS 8414-1 is to assess the fire performance of thermal insulation systems and curtain walls as exterior wall cladding systems including structural fire protection measures such as fire blocks or fire barriers. The following criteria are used for assessment: external spread of fire, internal spread of fire and mechanical performance. The resulting classification applies for the examined exterior wall cladding system only.